Why Compliance Audit is required?

The international RMG business is tremendously competitive and challenging; and as the days are passing the RMG importing countries, alongside its consumer preference for products are need to be met with internationally recognized standards and prerequisites. In this demanding condition it is essential for Bangladeshi RMG suppliers to improve compliance and regulatory standards in their factories. To deal with these international exporting requirements, RMG authorities in Bangladesh should immediately implement effective and resolute policies on housekeeping, material storage and handling, work station design, workers health and safety, fair wage, fair disciplinary action, and workplace violence. Though RMG is the most flourishing sector in Bangladesh; it is still imperative that each and every issue related to improvement of productivity, maintenance of product quality and betterment of factory conditions should be strictly followed to maintain our superior position in the global market. Owners of RMG factories must emphasize on employment conditions, working facilities and occupational safety and health management to be more competitive in the international trade of textile and clothing business. Moreover, regular practice of compliance codes of conduct can bring higher price of products, lower labor unrest, higher worker turnover rate and highest level of employee morality.

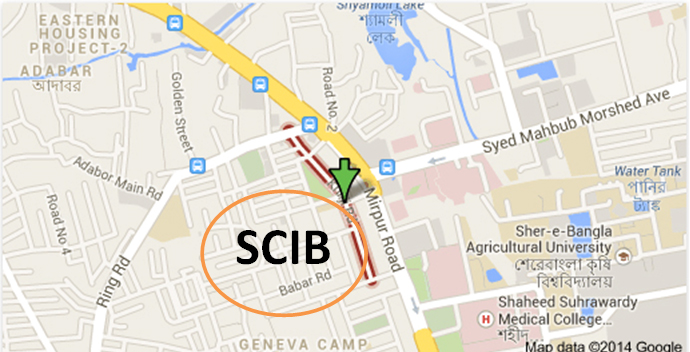

Following services are offered by SCIB:

Auditing: (Social Compliance audit)

Third Party Audit:

SCIB conducts third party social audit on factories, recommended and required by international buyers to comply with local law and international standards.

Initial Audit: Initial audit is conducted on new factories to screen the current problems and to locate solutions.

- Opening Meeting: Auditor will brief the intention of the visit and the whole auditing process.

- Factory tour: General Walk through of the factory and dorms (if applicable).

- Employee interviews (Confidential): conducted one-to-one of in small groups.

- Factory management interview: Review hiring process, factory rules, work schedules, and other procedures used by factory management.

- Country of Origin review: Reviewing production and shipping records.

- Closing meeting: Reviewing the finding and outcomes from the auditing process with factory management. Based on this review Audit team along with factory management come up with answers and then eventually implement these solutions. The audit recap is signed by both the auditor and factory management and an official copy is later given to factory.

Re-Audit: Large retailers usually asked the local supplier to go through an initial audit before placing the first order and they later propose them to have re-audit at the same facility at a certain interval to assess the progress based on initial assessment and finally its corrective action plan (CAP) on a bound manner.

If several serious issues were raised, the interval may even take as much as 6 months. If the result found very positive, then no re-audit needed at all.

- After the first audit, a few high-priority recommendations are strongly suggested;

- The factory is expected to implement corresponding corrective actions;

- During the following audit, these corrective actions are evaluated;

- The auditor also keeps looking for opportunities for improvement and writes new recommendations

Follow up Audit: The follow-up audit analyze the whole auditing process and look for required additional solutions and effective adaptations. Follow up audit conducted through the initial or re-audit corrective action time line.